|

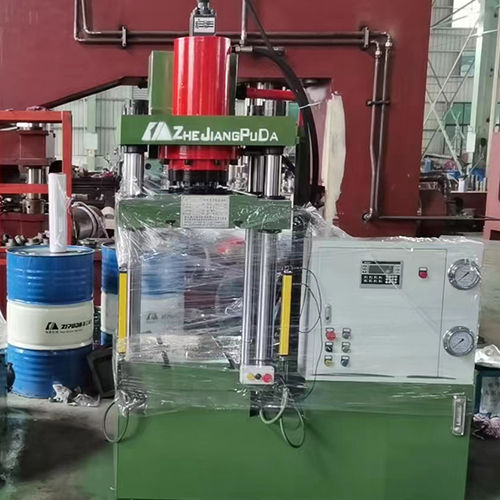

Elbow Cold Forming Machine

Price 12000 USD ($)/ Unit

Elbow Cold Forming Machine Specification

- Usage

- Industrial

- Power Source

- Hydraulic

- Condition

- New

- Product Type

- Elbow Cold Forming Machine

- Color

- White & Red

- Voltage

- 220-240 Volt (v)

Elbow Cold Forming Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ningbo port or Shanghai port

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 30 Days

- Packaging Details

- Export packaging standard

- Main Export Market(s)

- Central America, Australia, North America, South America, Western Europe, Middle East, Eastern Europe, Asia, Africa

- Main Domestic Market

- All India

About Elbow Cold Forming Machine

Elbow Cold Forming Machine is required for manufacturing elbows for piping systems. The machine is designed to bend metal pipes into specific shapes and sizes to meet the demands of different applications. Elbow cold forming machines use a hydraulic or mechanical press to shape metal pipes by applying pressure to them through the use of a die or mold. This machine finds usage in industries such as oil and gas, construction, plumbing, and HVAC, where piping systems are needed. Elbow Cold Forming Machine is a critical piece of machinery for companies manufacturing pipes and ensuring that the elbows produced are of high quality and meet the desired specifications.

Efficient Semi-Automatic Cold Forming Process

This Elbow Cold Forming Machine is engineered for precision and durability in the production of stainless steel pipe elbows. Its semi-automatic operation, combined with hydraulic power and frequency speed control, ensures smooth, consistent forming every cycle, meeting industrial standards while minimizing manual intervention.

Robust Construction and User-Friendly Controls

Built with premium stainless steel and finished in white and red, this machine offers reliable operation and ease of use. The simple frequency speed control system allows operators to adjust the forming speed easily, tailoring performance to specific material requirements and production volumes.

FAQs of Elbow Cold Forming Machine:

Q: How does the frequency speed control system benefit the elbow cold forming process?

A: The frequency speed control system allows precise adjustment of the machines forming speed, ensuring optimal shaping quality for different stainless steel grades and thicknesses while minimizing material stress.Q: What materials can the Elbow Cold Forming Machine process?

A: This machine is designed specifically for stainless steel, providing robust and consistent performance when forming pipe elbows for industrial applications.Q: When is it recommended to use this semi-automatic elbow forming machine?

A: Use this machine for medium to large-scale industrial production where consistent quality and reliable output are essential. Its suitable for environments that seek a balance between automation and manual oversight.Q: Where is this machine manufactured and supplied from?

A: The Elbow Cold Forming Machine is manufactured, distributed, exported, supplied, and traded by reputable companies based in China, ensuring access to global markets with reliable support.Q: What is the process involved in forming elbows with this machine?

A: The machine utilizes a hydraulic power source to apply controlled force on stainless steel pipes, shaping them into elbows through a cold forming process without heating, enhancing both precision and material integrity.Q: How is the Elbow Cold Forming Machine powered and what are its installation requirements?

A: It operates on a standard industrial voltage range of 220-240 Volts and requires hydraulic power. Installation requires stable electricity and hydraulic connections, as well as proper workspace for uninterrupted operation.Q: What are the main benefits of using this elbow forming machine in industrial settings?

A: Key benefits include high production efficiency, reduced manual effort, precision shaping, compatibility with stainless steel, and durable construction, resulting in cost-effective and reliable elbow manufacturing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inner High-Pressure Water Bulging Forming Machine Category

Pressing Water Bulging Forming Machine

Price 12000-220000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Source : Hydraulic

Condition : New

Voltage : 220240 Volt (v)

Usage : Industrial

Inner High-Pressure Water Bulging Forming Machine

Price 20000 USD ($) / Piece

Minimum Order Quantity : 1 Unit

Power Source : Other, Electric

Condition : New

Voltage : 380 V / 50 Hz / 3 Phase

Water Bulging Forming Machine

Price 15000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Source : Hydraulic

Condition : New

Voltage : 220240 Volt (v)

Usage : Industrial

Tee Cold Forming Machine

Price 15000-200000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Source : Hydraulic

Condition : New

Voltage : 220240 Volt (v)

Usage : Industrial

|

ZHEJIANG HAIZHUOLIKE HYDRAULIC TECHNOLOGY CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry