Most Popular Products

|

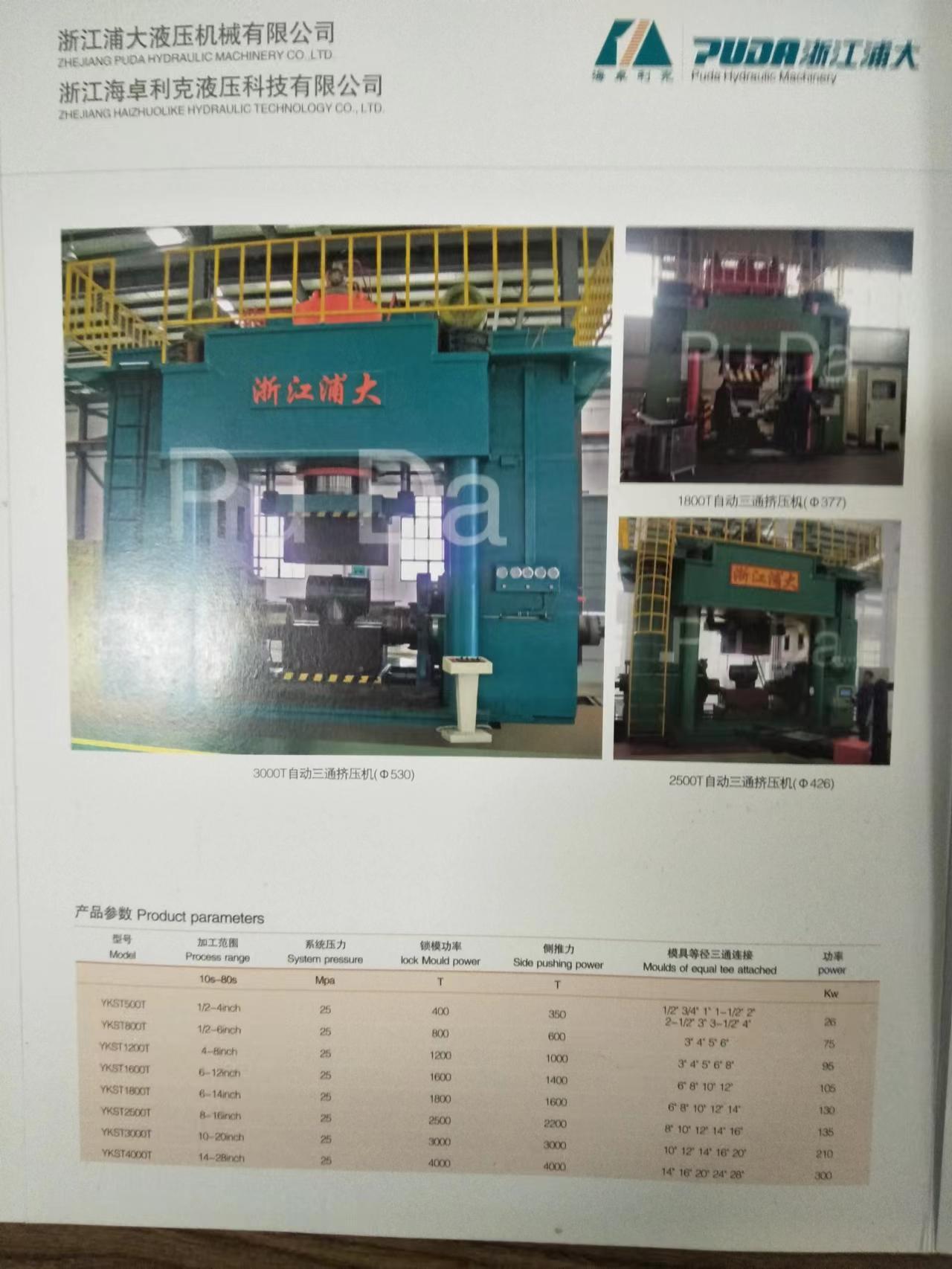

Tee Cold Forming Machine-

Price 25000 USD ($)/ Unit

MOQ : 1 Unit

Tee Cold Forming Machine- Specification

- Lubricating System

- Automatic

- Power Rating

- 22 kW

- Noise Level

- 75 dB

- Control System

- PLC Control

- Connectivity Options

- Standard I/O Ports

- Operating Temperature

- 0-45C

- Features

- High Production Efficiency, Easy to Operate

- Frame Type

- Heavy Duty Welded Frame

- Motor Power

- 22 kW

- Accuracy

- 0.2 mm

- Model No

- TCFM-300T

- Cooling System

- Water Cooling

- Machine Type

- Tee Cold Forming

- Voltage

- 380V

- Drive

- Hydraulic

- Production Capacity

- 100 pieces/hour

- Frequency

- 50 Hz

- Product Type

- Tee Cold Forming Machine

- Technology

- Hydraulic Cold Forming

- Power Source

- Electric

- Operating Type

- Semi-Automatic

- Power

- 22 kW

- Pressure

- 300 Tons

- Surface Treatment

- Paint Coated

- Dimension (L*W*H)

- 4200 x 1300 x 2300 mm

- Weight (kg)

- 5600 kg

- Color

- Blue & Yellow

- Usage & Applications

- Manufacturing Pipe Tee Fittings

- Applicable Fittings

- Equal and Reducing Tee

- Forming Time Per Piece

- 6-8 seconds

- Max Pipe Diameter

- DN50-DN400 mm

- Hydraulic Pressure

- 25 MPa

- Hydraulic Oil Capacity

- 380 Liters

- Material Processed

- Carbon Steel, Stainless Steel

- Main Cylinder Diameter

- 350 mm

- Die Change System

- Quick Change Mechanism

- Operator Interface

- Touch Screen

- Ram Stroke

- 300 mm

- Safety Features

- Emergency Stop, Interlock Guarding

Tee Cold Forming Machine- Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ningbo Port or Shanghai Port

- Payment Terms

- Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C)

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 30 Days

- Packaging Details

- Export Packaging Standard

- Main Export Market(s)

- Western Europe, Central America, Middle East, South America, Asia, Eastern Europe, North America, Australia

About Tee Cold Forming Machine-

Processing range size 1/4-4 inch;

Processing range size 5-12 inch;

Processing range size 14-24 inch;

Processing range size 18-32 inch;

Specification

|

Parameter |

Processing Size |

Clamping Force |

Pushing Force |

Working Pressure |

Power |

Table Size |

Weight |

|

HJ-T89 |

1/2"-3" |

4500 |

4000x2 |

25 |

55 |

660*660 |

22 |

|

HJ-T114 |

1/2"-4" |

5500 |

4900x2 |

25 |

62 |

700*700 |

25 |

|

HJ-T168 |

2"-6" |

8000 |

7000x2 |

25 |

90 |

1000*1000 |

56 |

|

HJ-T219 |

2"-8" |

12500 |

11000x2 |

25 |

110 |

1100*1100 |

68 |

|

HJ-T273 |

4"-10" |

15000 |

14000x2 |

25 |

135 |

1350*1350 |

150 |

|

HJ-T325 |

5"-12" |

22000 |

18000x2 |

25 |

276 |

1800*1800 |

270 |

|

HJ-T406 |

6"-16" |

26000 |

25000x2 |

25 |

295 |

1800*1800 |

320 |

|

HJ-T508 |

8"-20" |

35000 |

30000x2 |

25 |

350 |

1800*1800 |

360 |

|

HJ-T610 |

10"-24" |

45000 |

40000x2 |

25 |

400 |

2000*2000 |

420 |

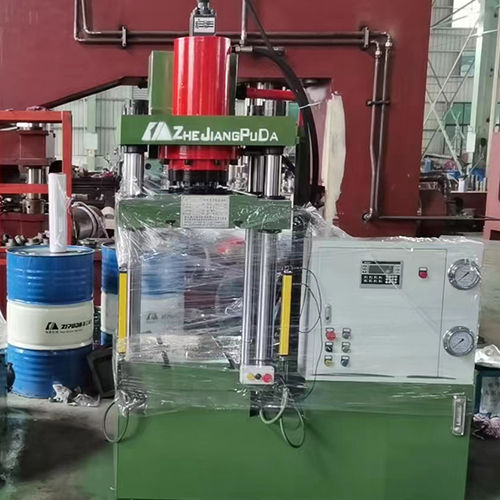

Advanced Hydraulic Cold Forming for Tee Fittings

The TCFM-300T combines a heavy-duty hydraulic press with innovative cold forming technology to shape both equal and reducing tee fittings efficiently. Designed for versatility, it handles materials such as carbon steel and stainless steel, delivering consistent accuracy and outstanding throughput.

Intuitive Operation and Quick Changeover

Featuring a touch screen operator interface and a quick-change die mechanism, the machine allows operators to switch between fitting types swiftly. Semi-automatic controls, PLC system integration, and automatic lubrication enhance smooth operation for both experienced technicians and new users.

Built-In Safety and Durable Construction

Operator safety is ensured by emergency stop systems and interlock guarding. The sturdy welded frame and advanced cooling contribute to reliable, long-term performance, while a noise level below 75 dB supports a safer working environment in manufacturing plants.

FAQs of Tee Cold Forming Machine-:

Q: How does the Tee Cold Forming Machine ensure precision and consistency in forming pipe tee fittings?

A: The machine utilizes hydraulic cold forming with controlled pressure up to 300 tons, and a PLC-operated system ensures accuracy within 0.2 mm. The robust main cylinder and quick-change die mechanism maintain consistent shapes and sizes for both equal and reducing tee fittings.Q: What types of materials can the TCFM-300T process, and what are its maximum pipe diameter capabilities?

A: This model can handle both carbon steel and stainless steel pipes with diameters ranging from DN50 to DN400 mm, supporting a wide range of industry standards and applications.Q: When should die changes be performed, and how does the quick-change system benefit production?

A: Die changes are recommended when switching between different tee fitting sizes or types. The quick-change mechanism allows fast, efficient transitions with minimal downtime, maximizing hourly output and productivity.Q: Where is the TCFM-300T most commonly used, and what industries benefit from its capabilities?

A: The machine is widely used in pipe fitting manufacturing plants, by distributors, exporters, and suppliers, mainly in the construction, plumbing, and oil & gas sectors requiring high-quality pipe tee fittings.Q: What is the forming process of the machine and how long does it take per piece?

A: It cold forms tees using targeted hydraulic pressure, shaping the fitting within a dedicated die. Each piece is produced in 68 seconds, ensuring fast production cycles suitable for large-scale manufacturing.Q: What safety features are included to protect operators during operation?

A: Safety is enhanced with an emergency stop button, interlock guarding, and noise level management (75 dB), ensuring both immediate response capabilities and a comfortable working environment.Q: How does the TCFM-300T improve operational efficiency for manufacturers?

A: Its high production capacity (up to 100 pieces/hour), automatic lubrication, efficient cooling, and semi-automatic controls all minimize operator workload and downtime, yielding reliable and cost-effective output.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

ZHEJIANG HAIZHUOLIKE HYDRAULIC TECHNOLOGY CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry